VEHICLE LOADING & UNLOADING TIPS

Truck unloading is a daily activity in many businesses. It is also a regular source of injuries to the driver, workers and visitors. Employers have a responsibility to ensure. they maintain a safe working environment. Forklift operators are also responsible for the safety of others in the unloading area. This guideline should be used to help management establish safe work procedures as it relates to vehicle unloading.

Establish an Unloading Area:

- Area should be level to help maintain stability of the truck and trailer. The ground should be free of potholes and debris.

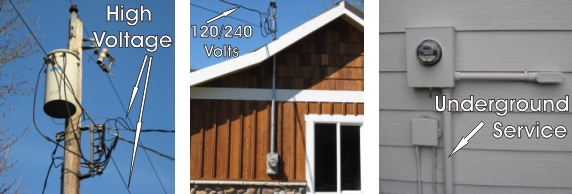

- Area should be free of overhead electric lines.

- Area should be clear of other traffic — vehicles or foot. Pedestrians, the truck driver, or others employees not involved in the unloading process should be clear of the area.

- Area should have sufficient lighting for early morning or evening unloading.

- If possible, the designated area should be a one-way route to prevent the need for vehicles to back up. If a driver is required to back the vehicle, a spotter should be used to protect pedestrians and property.

Guidelines for Truck Drivers:

After checking into the office, the driver should proceed to the designated area and remove tarps, straps, or other load securement devices. Secure this material so it is not an obstruction to the forklift operator during the unloading process.

Driver should secure vehicle, apply brakes, and turn off engine, as appropriate, to prevent unsafe movement during the unloading operation.

Driver should proceed to a designated area (safe zone) located away from the truck and outside of the unloading area. The driver should remain in that area during the unloading operation.

NO material should be unloaded nor should any forklifts be operating in the area around the truck until the driver has completed all of the tasks above and moved to the designated safe zone.

Forklift Safety Tips for Transport Loading and Unloading

Safety Tips for Transport LoadingThe forklift is a material handling piece of equipment that was designed to load, unload, and transport heavy objects and materials. They are used throughout warehouses mainly and are a crucial part of the daily working processes. Trained workers are the only ones qualified to operate forklifts because as helpful as forklifts are, they can be dangerous when not operated correctly. Preventing accidents on forklifts depends on safety practices and training. Loading and unloading protocols is one important part of safety training that can help workers prevent accidents and save lives.

SAFE HANDLING PREPARATION

Before an operator can handle a load, they need to be aware of any possible hazards that could cause the forklift to tip over or cause any damage to people or the surroundings. These hazards are off-center loads which can cause tip overs, overloading which can cause tip overs and falling loads, and damaged or loose loads that can come unstable and hurt someone. To ensure the safe handling of a load, workers need to make sure the load is secure to stabilize it, center the load as much as possible, avoid overloading, understand the forklift’s load capacity, and use the load extension backrest for security.

LIFTING A LOAD

When attempting to lift a load, it is important to be conscious of any hazards like an insufficient clearance, falling loads, and stuck loads. Safety tips for lifting a load include checking the overhead clearance to ensure there are no objects that could in contact with the load, such as lighting, pipes, and sprinklers. This step is especially true when operating in a confined space like a truck trailer. Lift the load very carefully above the lower stack about four inches. Raise the load until it’s clear off the ground and then tilt the mast back slightly to rest the load against the backrest extension to help stabilize it and provide support when traveling. Make sure the load is not touching any objects and can’t catch any obstructions. Return the lift control lever to the neutral position.

LOWERING A LOAD

The biggest hazards present when lowering a load on a forklift are falling loads that can hit other workers, and hitting objects that can fall and strike others or come into contact with other unstable objects. Before a load is lowered, make sure the load is slightly tilted back to stabilize it, out of its neutral position. First, ensure the load is secured before moving, tilt the mast backward to stabilize the load, and move the forklift 8-12 inches away from the load to get it ready for lowering. Stop the truck, return the mast to the vertical position before lowering the load, lower the load so that its lowest point is 6-8 inches away from the floor, and keep the load at a safe travel height while moving with the load.

How to load your forklift:

- While loading, ensure the goods are evenly distributed, correctly stacked and positioned across both forks to avoid any collapsing and damage to the contents. Do not lift a load with one fork.

- Ensure the load is fully secure before moving the forklift. Use securing measures such as ropes or bindings if needed.

- Never overload a forklift truck as it’s an accident waiting to happen. Know the capacity of your forklift and any attachments being used and never exceed this capacity. An overloaded vehicle can cause the rear tyres to be raised off the ground and may cause the forklift to tip over.

- Do not use the tip of the forks as a lever to raise a heavy load or push a load with the tip of the forks.

- It is important to ensure that the goods are tilted back with the forks sitting low whilst transporting in order to increase truck stability. Keep the centre of gravity of the load as low to the ground and as close to the front wheels as possible: Carry the load at the lowest position possible, 4 – 6 inches from the ground. Tilt the mast back and position the heaviest part of the load against the carriage.

Safety Tips: Loading & Unloading

Properly loading and unloading freight is integral to our continued success at Minimax. It ensures that the truck you’re driving is loaded safely, which safeguards against our drivers getting injured on the job and it allows us to deliver damage-free products to our customers.

Here are five great safety tips for loading and unloading freight:

1. Distribute weight evenly

Having a well-balanced pallet and trailer will prevent against the tipping or falling over of the pallet or product. Remember to place the heavier objects on the bottom of the pallet and the lighter object on top, and double-check that no boxes are misaligned or overhanging. Let the pallet act as a bumper for forklifts or pallet jacks, not the packages!

2. Use cardboard corner beads

Cardboard corner beads- image of box with yellow strapping

Cardboard corner beads protect against the misalignment of boxes on a pallet while simultaneously ensuring the protection of our customers’ products by protecting the corners of boxes from strapping.

3. Use straps

Strapping the pallet with nylon or metal strapping will add an extra level of assurance that whatever is on the pallet will stay on the pallet during transportation.

4. Shrink wrap properly

Don’t skimp out on shrink wrap! Make sure the pallet is wrapped four or five times with a particular focus on the bottom of the pallet where a shift in product could result in uneven weight distribution. If you need extra strength when wrapping, twist the shrink wrap as you make your away around the pallet.

5. Utilize load protectors

A load protector is a flat, empty piece of cardboard that can be placed every few rows to stabilize loose boxes while also helping with weight distribution.

Steps to loading safely:

- Get good quality ramps, rated to handle the size and weight of your quad or side x side and are long enough to allow for a safe loading angle into your truck – jacked up trucks will require longer ramps.

- Secure your ramps to your truck with straps and check that the ramps can’t slip or slide out as you apply power up the ramps.

- Wear a helmet when loading/unloading in case something happens. If you have a side x side wear your seatbelt, you want to be inside the machine in the event of a rollover.

- Use 4 wheel drive and low range and apply the throttle smoothly as you climb the ramps.

- Get your weight forward – just like climbing a hill when riding you should be prepared to lean forward or stand to move your weight forward as required for the slope of your ramps.